Freeze-Ease PRO

When faced with a seized component, excessive force can often lead to more problems than solutions. Breaking a bolt or attempting to unscrew a heavily corroded nut might not always be catastrophic, but dealing with a snapped spark plug, fuel injector, or glow plug can be both costly and time-consuming.

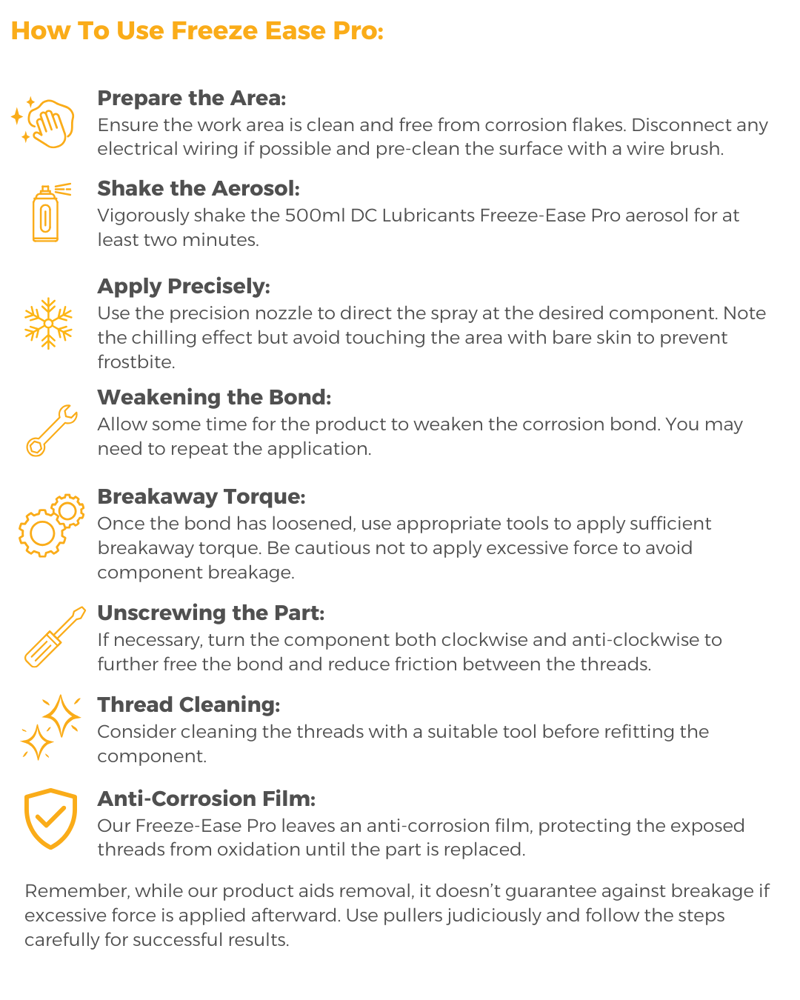

DC Lubricants presents a chemical approach to address this challenge. Our Freeze-Ease Pro is engineered to dissolve the robust connection between the threads of components and the cylinder head. We leverage scientific principles and advanced lubrication, rather than physical force, to resolve such issues.

How it works:

- Temperature Contraction: The Freeze-Ease Pro rapidly chills the applied area to -40 degrees Celsius. This sudden temperature change promotes micro-cracking, effectively breaking apart the fused surfaces.

- PTFE-Based Lubricant: Our formula includes a powerful PTFE-based lubricant. This reduces stress on the component during extraction by minimizing friction.

- Corrosion Inhibitor Additive: Extra benefits come from our potent corrosion inhibitor additive. Plus, our composition is free from acids and silicone.